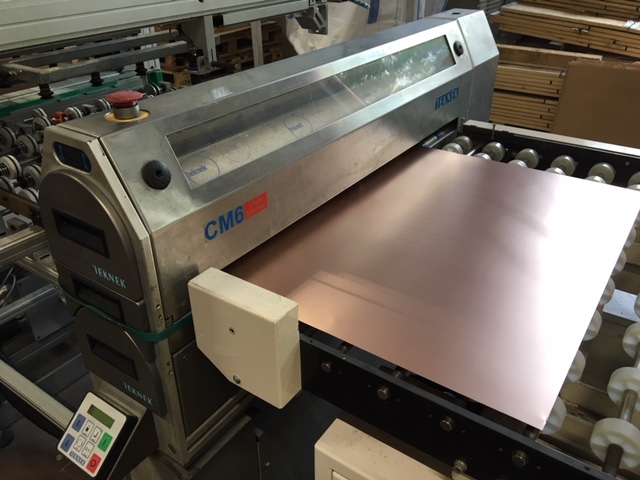

In recent years Com.Int.El. has worked in order to automate as much as possible the production process of the laminate cutting, so as to minimize fingerprints or damages caused by the contact of the operator with the material or dust resulting from its cutting. For this reason, we have not only installed a fully automated laminate cutting machine, from sheet loading to panel unloading, which has already been in operation since 2013, but we have also implemented this production line with a cleaning machine. The latter, installed between the Shoda bevelling machine module and the automatic unloader that places the finished panel on the pallet, is able to clean and remove any residue from the panel before stacking in order to eliminate the risk of abrasion on the panel surface caused by dust.